Understanding the intricacies of electrical systems can be complex, but for anyone working with industrial machinery, a 9 Lead 3 Phase Motor Wiring Diagram is an essential piece of information. This diagram provides the blueprint for connecting a versatile type of three-phase motor, allowing for various voltage configurations and operational modes. Grasping the 9 Lead 3 Phase Motor Wiring Diagram ensures safe and efficient operation of your equipment.

Decoding the 9 Lead 3 Phase Motor Wiring Diagram

A 9 lead three-phase motor is a highly adaptable motor designed to operate at different voltage levels and can be configured for various applications. The nine leads (or terminals) emerging from the motor's winding offer flexibility in how the motor is connected to the power supply. This versatility is particularly useful in situations where the available power voltage might change or when a single motor model needs to serve multiple purposes. The core principle behind a 9 lead motor is the ability to rearrange its internal windings into different series and parallel combinations. This allows for:

- Operation at lower voltages (e.g., 230V) by connecting windings in parallel.

- Operation at higher voltages (e.g., 460V) by connecting windings in series.

- Configuring the motor for specific starting methods, such as delta or wye (star) configurations.

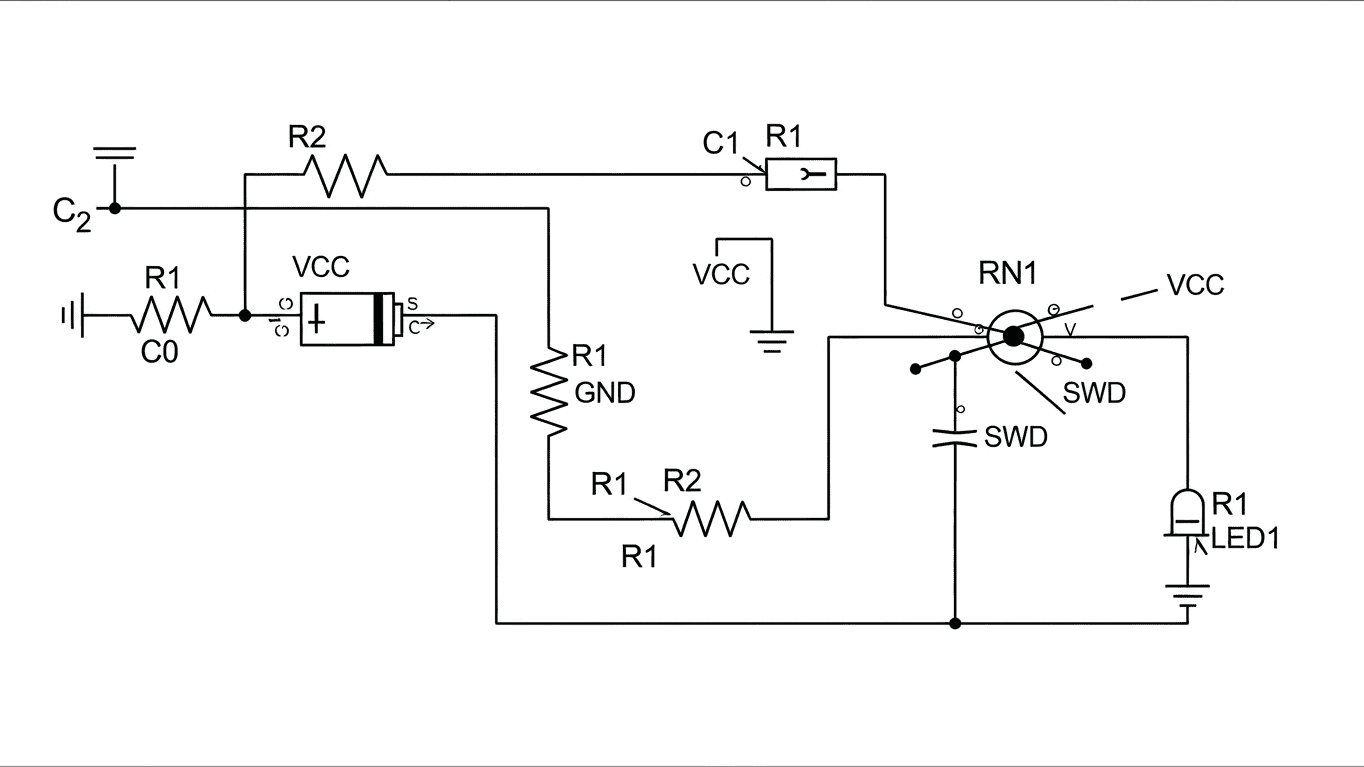

The 9 Lead 3 Phase Motor Wiring Diagram is crucial because it visually represents these winding combinations and the corresponding connection points for the incoming power. Without it, attempting to wire such a motor would be guesswork, leading to potential damage to the motor, the power supply, or even safety hazards for personnel. The diagram typically labels each of the nine leads, often with numbers (e.g., T1 through T9) and indicates how these leads should be connected together internally and to the external power source (L1, L2, L3). A typical diagram might show different connection schemes for different voltages or operational modes:

- Low Voltage Connection (Parallel): This involves connecting certain leads together to create parallel paths for current, thus reducing the overall voltage requirement per winding.

- High Voltage Connection (Series): Here, leads are connected in sequence, increasing the total voltage the windings are designed to handle.

- Wye (Star) Connection: This configuration connects one end of each winding together to a common neutral point, used for starting the motor efficiently.

- Delta Connection: In this setup, the windings are connected end-to-end, forming a closed triangle, often used for running the motor at its full speed.

Referencing the 9 Lead 3 Phase Motor Wiring Diagram is paramount for proper installation and maintenance. It dictates which leads connect to which power lines and how internal connections should be made to achieve the desired voltage and starting characteristics. Mistakes in following the diagram can lead to:

| Incorrect Connection | Consequence |

|---|---|

| Connecting for high voltage on a low voltage supply | Motor may not start or will run very slowly, potentially overheating. |

| Connecting for low voltage on a high voltage supply | Motor will likely burn out immediately. |

| Incorrect internal winding connections | Motor may run in the wrong direction, lack starting torque, or sustain internal damage. |

Therefore, always consult the specific 9 Lead 3 Phase Motor Wiring Diagram provided by the manufacturer for the motor you are working with. Ensuring the correct wiring is fundamental for the longevity and safe operation of the motor.

For accurate and safe implementation of your three-phase motor setup, it is highly recommended to refer to the specific 9 Lead 3 Phase Motor Wiring Diagram provided by the motor manufacturer.