Understanding the intricacies of electrical systems can seem daunting, but grasping the fundamentals of a 9 Lead Motor Wiring Diagram is a crucial step for anyone working with electric motors. This diagram serves as a roadmap, guiding you through the connections needed to operate these powerful machines safely and efficiently. Whether you're a seasoned technician or a curious hobbyist, a clear comprehension of a 9 Lead Motor Wiring Diagram is essential.

Decoding the 9 Lead Motor Wiring Diagram

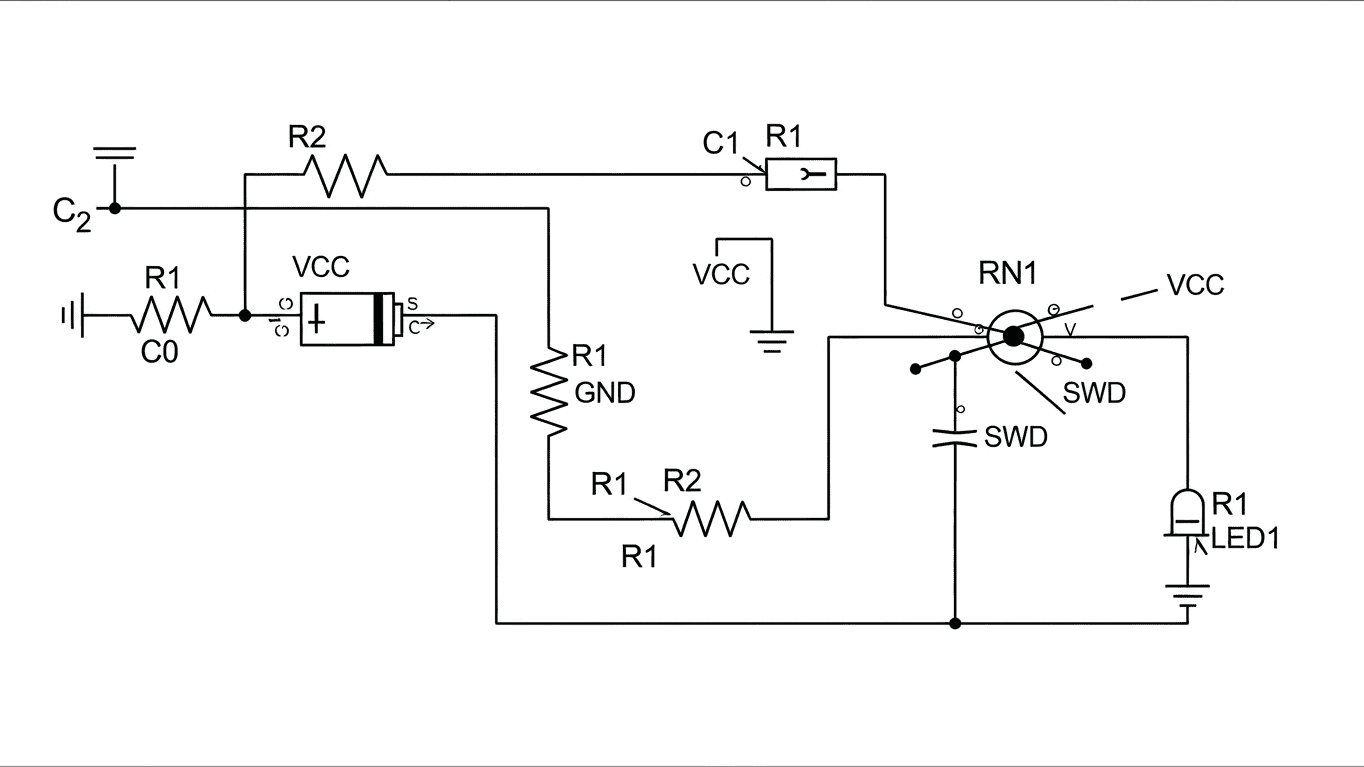

A 9 Lead Motor Wiring Diagram specifically refers to the schematic for a three-phase motor that offers a high degree of flexibility in its configuration. These motors typically have nine distinct leads emerging from their windings. This allows for multiple connection possibilities, enabling the motor to be operated in various voltage configurations and for different operational modes, such as series or parallel connections of the windings. The ability to adapt a single motor to different power supplies and performance requirements is a significant advantage.

The nine leads are usually categorized by their function and the winding group they belong to. For instance, you might find leads designated for the start and run windings. These are further broken down to allow for series, parallel, or wye (star) and delta configurations. A typical setup might involve:

- Three leads for one set of windings.

- Three leads for another set of windings.

- Three leads for a third set of windings.

These combinations allow for different voltage ratings. For example, a motor might be able to run on 230V, 460V, or even higher voltages depending on how these leads are interconnected.

Properly interpreting and implementing a 9 Lead Motor Wiring Diagram involves understanding the relationship between the leads and the desired output. Here are some common configurations:

- Low Voltage (e.g., 230V): In this configuration, the windings are often connected in parallel to draw more current and operate effectively at lower voltages.

- High Voltage (e.g., 460V): For higher voltages, the windings are typically connected in series to increase the overall resistance and reduce the current draw.

- Reversing Rotation: By swapping the connections of two of the three phases, the direction of motor rotation can be reversed. This is a fundamental aspect of motor control.

A simplified table illustrating potential connections for a 9-lead motor might look like this:

| Configuration | Voltage | Winding Connection |

|---|---|---|

| Low Voltage | 230V | Parallel |

| High Voltage | 460V | Series |

For a comprehensive understanding and to ensure accurate installation, refer to the specific 9 Lead Motor Wiring Diagram provided by the motor manufacturer. This will detail the exact lead markings and connection points for your particular model.

To gain a deeper understanding and to find the precise wiring configuration for your specific needs, consult the detailed documentation and schematics available in the manufacturer's manual.