Understanding a 9 Wire Motor Wiring Diagram is essential for anyone working with these versatile electric motors. These diagrams are your roadmap to correctly connecting the motor's various windings to power and control systems. Whether you're a hobbyist, a technician, or an engineer, having a clear grasp of a 9 Wire Motor Wiring Diagram can save you time, prevent damage, and ensure your motor operates as intended.

Decoding the 9 Wire Motor Wiring Diagram

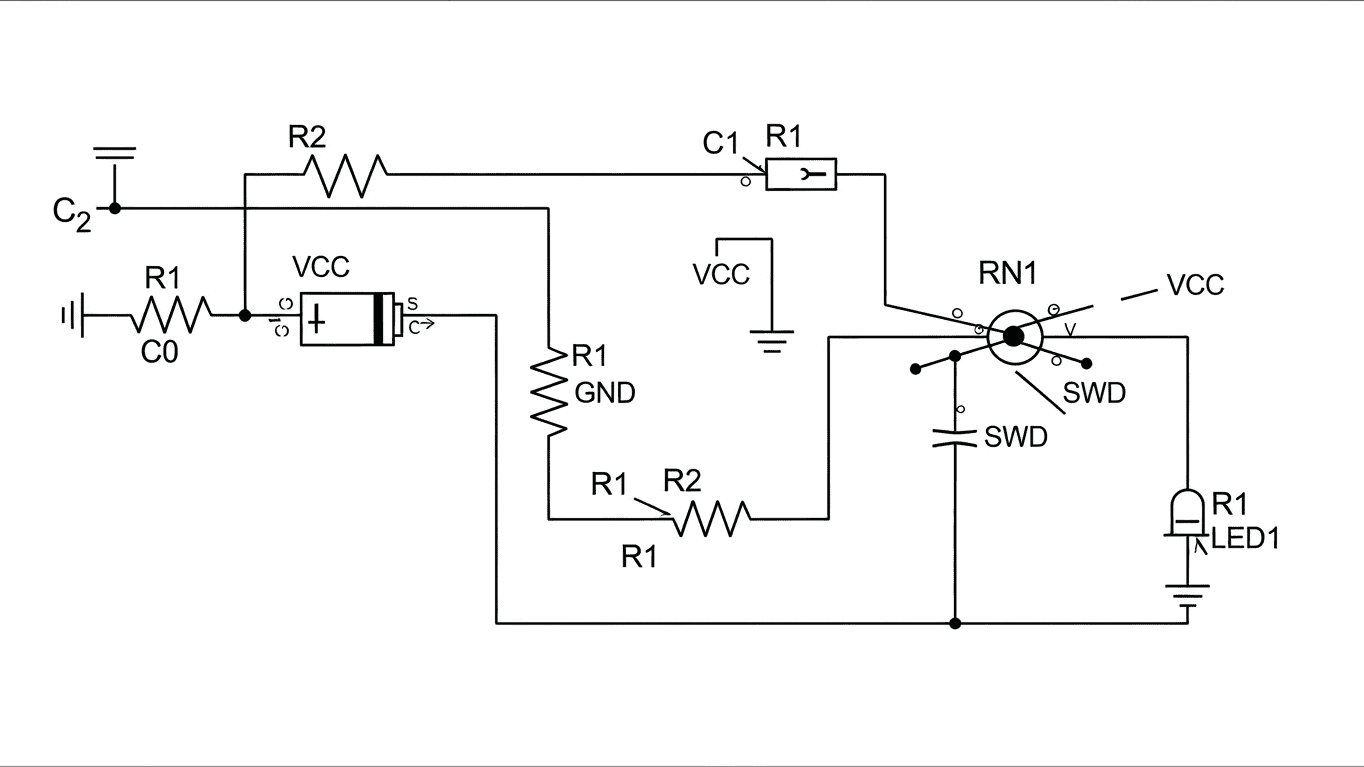

A 9 wire motor, often referred to as a dual voltage or multi-speed motor, offers flexibility in operation by providing multiple connection possibilities. The "9 wires" refer to the leads emanating from the motor's internal windings. These windings are typically arranged in specific configurations to allow for different voltage inputs or speed settings. The primary purpose of a 9 Wire Motor Wiring Diagram is to illustrate how to connect these nine individual wires to achieve the desired operational mode. Without this diagram, attempting to wire such a motor would be a matter of guesswork, which can lead to incorrect operation or even motor burnout.

The complexity arises from the fact that these nine wires represent combinations of windings, each designed for a specific function. Typically, these motors have two sets of windings: a low-voltage set and a high-voltage set. The 9 Wire Motor Wiring Diagram will show how to connect these windings in series or parallel to accommodate the power supply available. For example, connecting the windings in parallel might be suitable for a lower voltage supply, while a series connection might be used for a higher voltage supply. The diagram will also indicate how to connect any internal thermal protection devices or start/run capacitors that are part of the motor's integrated system. Proper interpretation of these diagrams is paramount for safe and efficient motor operation.

Here are some common uses and scenarios where a 9 Wire Motor Wiring Diagram is crucial:

- Dual Voltage Operation: The most common application is to run the motor on either a lower voltage (e.g., 115V) or a higher voltage (e.g., 230V) without changing the motor itself. The diagram dictates the wiring to achieve this.

- Multiple Speeds: Some 9 wire motors are designed for variable speed operation by reconfiguring the windings. A 9 Wire Motor Wiring Diagram will detail the connections for each speed setting.

- Reversing Direction: The diagram can also show how to reverse the direction of motor rotation by swapping specific winding connections.

- Integration with Control Systems: For automated systems, the diagram helps in understanding how to connect the motor to control panels, relays, and other electrical components.

Here's a simplified representation of wire categories you might find:

| Wire Group | Typical Function |

|---|---|

| Common/Line | Connects to the power source. |

| Low Voltage Windings | Used for lower voltage operation. |

| High Voltage Windings | Used for higher voltage operation. |

| Capacitor Wires | For connecting start or run capacitors. |

| Internal Connections | These wires are internally connected within the motor and the diagram shows where to break or join them. |

When faced with a 9 Wire Motor Wiring Diagram, it's important to follow it meticulously. We highly recommend referring to the specific 9 Wire Motor Wiring Diagram that came with your motor or is provided by the manufacturer for the most accurate and safe installation.