Understanding the intricacies of electrical control systems is crucial for many industries, and the 86 Lockout Relay Wiring Diagram plays a vital role in ensuring safety and operational integrity. This diagram provides a visual roadmap for how these essential safety devices are connected and function within a larger electrical circuit. Whether you're a seasoned technician or just starting to learn about industrial controls, grasping the 86 Lockout Relay Wiring Diagram is a fundamental step towards safe and effective system management.

What is an 86 Lockout Relay and How is it Wired?

An 86 Lockout Relay, often referred to as a lockout or master relay, is a critical safety component in electrical control systems. Its primary function is to prevent a machine or process from restarting after a fault condition or a manual shutdown has occurred, until the fault is cleared and the relay is manually reset. This ensures that personnel can safely work on equipment or address the root cause of a problem without the risk of unexpected energization. The importance of correctly wiring an 86 Lockout Relay cannot be overstated , as it directly impacts the safety of personnel and the reliability of the equipment.

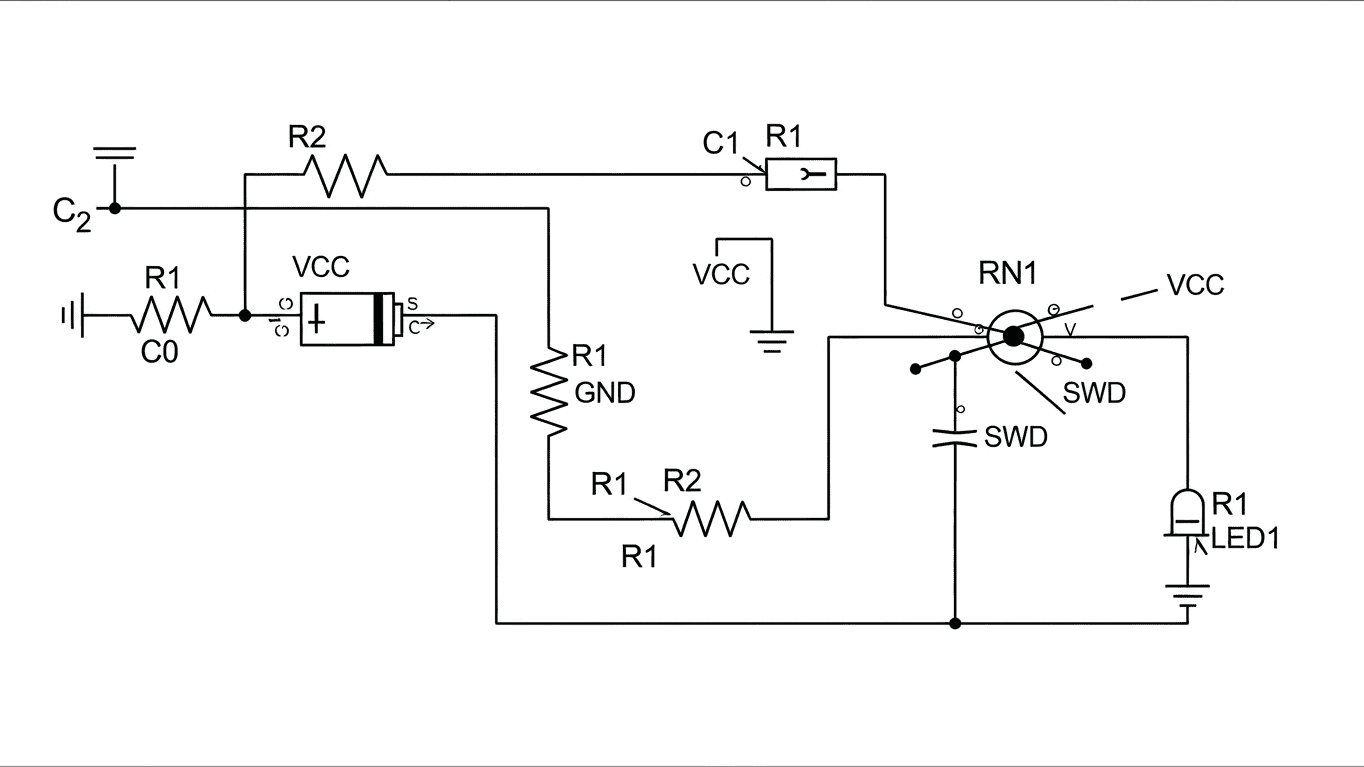

The wiring of an 86 Lockout Relay typically involves several key connections. These relays have control coils that, when energized, latch in their state. This latching mechanism is what provides the "lockout" functionality. When a trip condition occurs, a signal is sent to de-energize the relay's coil, causing it to unlatch and open its contacts. These contacts are usually wired in series with the control circuits of the machinery, effectively interrupting power and preventing restart. Here's a general overview of common connections:

- Control Power Input: The relay needs a source of control power to energize its coil.

- Trip Input: This is the signal that initiates the lockout sequence, often coming from protective devices like overcurrent relays or emergency stop buttons.

- Seal-in/Latching Circuit: Once energized, a contact on the relay typically provides a path for control power to maintain its own coil energization, holding it in the latched position.

- Load/Control Output Contacts: These contacts are wired into the control circuits of the equipment being protected, acting as a gatekeeper to prevent operation.

- Reset Input: A manual reset button or switch is wired to de-energize the coil and allow the relay to be unlatched, usually requiring an intentional action to restore operation.

The specific configuration of an 86 Lockout Relay Wiring Diagram can vary based on the manufacturer and the application. However, the fundamental principles of tripping, latching, and interrupting control power remain consistent. A simplified example of how a trip signal might interact with the relay's coil and its output contacts can be visualized in the following table:

| Condition | Relay Coil State | Output Contacts State | Equipment Operation |

|---|---|---|---|

| Normal Operation | Energized (Latching) | Closed | Enabled |

| Fault/Trip Signal | De-energized | Open | Disabled (Locked Out) |

| Manual Reset | Energized (Ready to Latch) | Open (Until Reset) | Disabled (Locked Out) |

For detailed, application-specific instructions, it is essential to refer to the manufacturer's documentation. The diagrams provided by the relay manufacturer offer the most accurate and comprehensive guide to its wiring. Always consult these resources before undertaking any wiring or maintenance to ensure safety and proper functionality.

To gain a deeper understanding and ensure correct implementation, please refer to the manufacturer's official documentation and specific 86 Lockout Relay Wiring Diagram for your model.