Understanding the 7.5Hp Baldor Motor Capacitor Wiring Diagram is crucial for anyone working with these powerful electric motors. Whether you're performing maintenance, troubleshooting a problem, or installing a new motor, having a clear grasp of the capacitor's role and how it's wired ensures safe and efficient operation. This diagram serves as a roadmap, guiding you through the connections that allow the motor to start and run optimally.

The Role and Function of Capacitors in Baldor Motors

Single-phase electric motors, like many 7.5Hp Baldor models, require a little extra help to get started. Unlike three-phase motors that have a naturally rotating magnetic field, single-phase motors need a way to create this rotation. This is where the capacitor comes in. The capacitor, often referred to as a start capacitor or a run capacitor (or sometimes both), provides a phase shift to an auxiliary winding within the motor. This temporary or continuous phase shift generates the necessary rotating magnetic field, allowing the motor to overcome its inertia and begin spinning.

There are generally two types of capacitors used in single-phase motors: start capacitors and run capacitors. A start capacitor is a high-capacitance, short-duration device connected in series with the start winding. It provides the initial boost needed to get the motor rotating. Once the motor reaches a certain speed, a centrifugal switch or an electronic relay disconnects the start capacitor. A run capacitor, on the other hand, is a lower-capacitance, continuous-duty device that remains connected in the circuit even after the motor is running. It helps to improve the motor's efficiency, power factor, and running torque. For a 7.5Hp Baldor motor, the specific type and rating of the capacitor are critical for proper operation. Proper capacitor selection and wiring are paramount to the motor's longevity and performance.

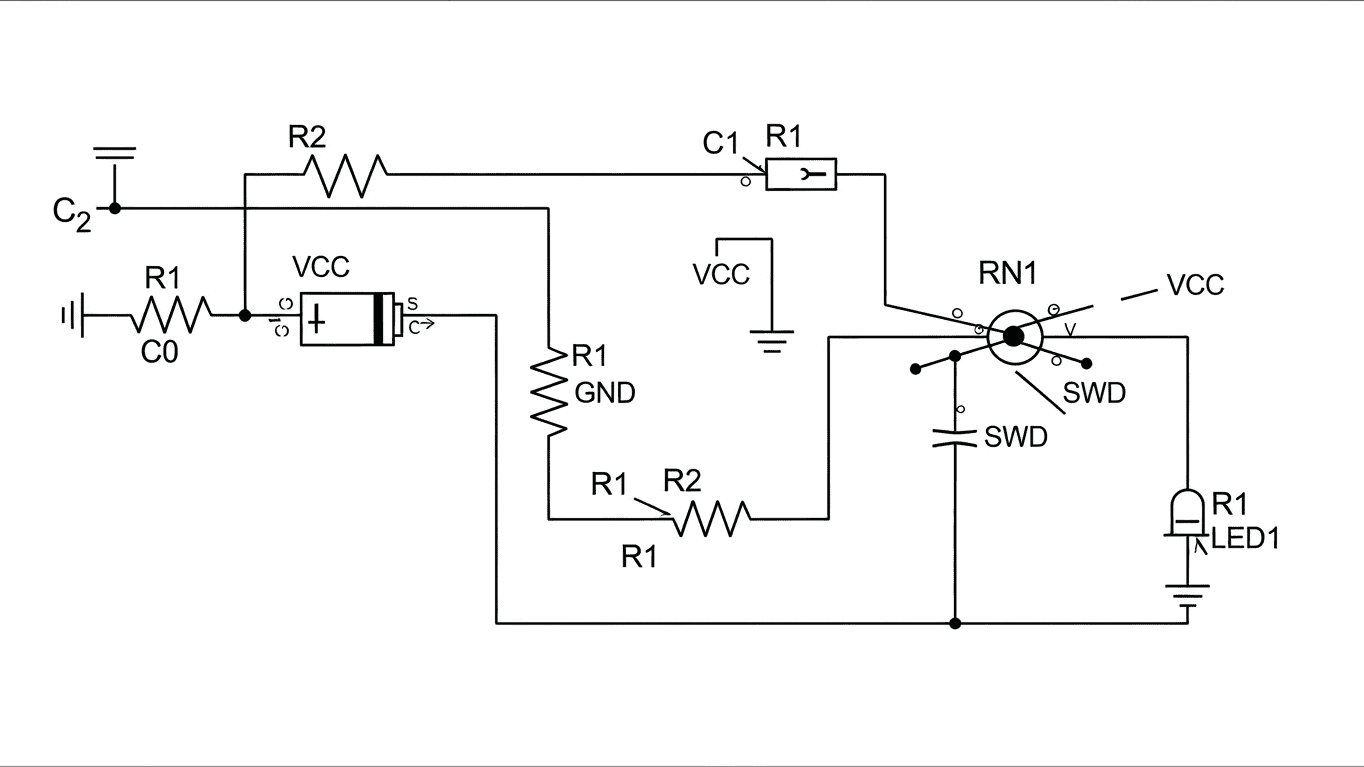

The 7.5Hp Baldor Motor Capacitor Wiring Diagram details exactly how these components are connected to the motor's terminals and the power supply. It will typically show:

- The location of the motor's terminal box.

- Connections for the incoming power lines (L1 and L2, or hot and neutral).

- The main winding and the auxiliary (start) winding.

- The capacitor(s) and their connection points.

- Any associated relays or switches, such as centrifugal switches.

Here's a simplified representation of common connections:

| Component | Connection Point |

|---|---|

| Start Capacitor | In series with the start winding, typically switched by a centrifugal switch. |

| Run Capacitor | In series with the auxiliary winding, remaining in the circuit during operation. |

| Main Winding | Connected to the power supply. |

| Auxiliary Winding | Connected to the power supply through the run capacitor and/or the start capacitor circuit. |

Referring to the specific 7.5Hp Baldor Motor Capacitor Wiring Diagram for your motor model is essential. This will ensure you are connecting the correct type and rating of capacitor and that all connections are made according to safety standards. Incorrect wiring can lead to the motor not starting, overheating, reduced performance, or even permanent damage.

To ensure you have the most accurate and detailed guidance for your specific 7.5Hp Baldor motor, please consult the official documentation and wiring diagrams provided by Baldor Electric. This will be the most reliable source for your capacitor wiring needs.